Application prospect of peanut shelling machine

Peanuts have long been a staple in our daily lives, offering a wide range of delicious products that are enjoyed globally. The mechanization of peanut production has become a vital component of agricultural modernization, playing a significant role in ensuring sustained and rapid growth in the agricultural and rural economy. Next, we’ll introduce the various applications of peanut shelling machines, the progress made in mechanization, and the potential for further development and market expansion.

Advancing Peanut Production Mechanization

In recent years, there has been a steady growth in the adoption of peanut machinery and equipment, leading to improved operational efficiency and the expansion of social services. However, it’s essential to note that the mechanization level of peanut shelling machines varies across different regions. Economically developed areas and demonstration zones have embraced higher-grade machinery, while some areas still rely on traditional manual shelling methods with lower labor productivity.

Nonetheless, the 21st century brought about significant changes in agricultural structure adjustment, paving the way for positive and far-reaching influences on peanut machinery development. The mechanization of peanut production entered a new phase of growth, with the industry witnessing increased demand and a market conducive to the development of peanut shelling machines. This transformation has played a pivotal role in driving the rural economy’s development.

Promoting Mechanization through Incentives

To foster the widespread adoption of peanut machinery and boost mechanization, various regions have implemented preferential policies and measures to encourage and support farmers in purchasing such equipment. Furthermore, efforts have been made to develop peanut machinery operation services, creating a renewed interest among farmers to invest in these machines.

The deep processing of peanut products has experienced a surge in demand both domestically and internationally, pushing for enhanced levels of modernization in peanut shelling machines. These machines have significantly improved labor productivity and reduced labor intensity, making peanut processing more efficient and cost-effective. As a result, the advancement of technology in the peanut processing industry has provided ample space for the further development of peanut shelling machines.

Application of Peanut Shelling Machines

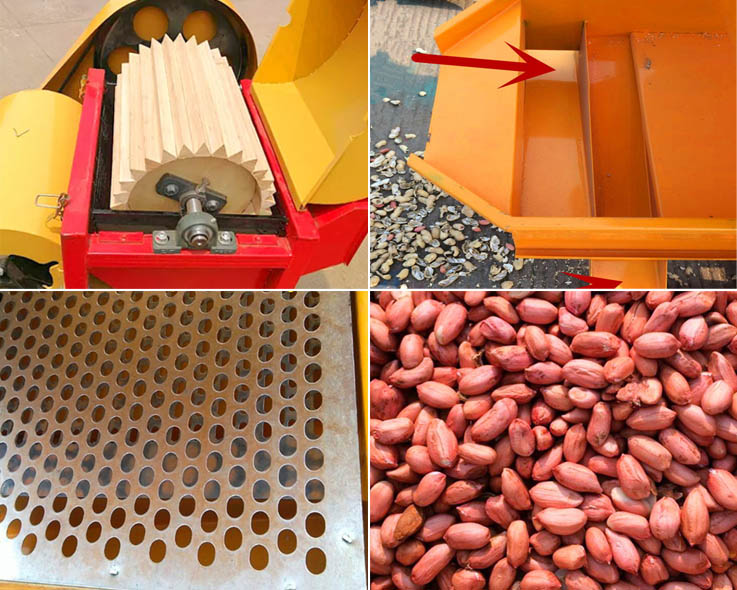

Peanuts in the Shell:

Peanut shelling machines play a vital role in the efficient removal of shells from peanuts, streamlining the process and ensuring high-quality, intact kernels. The availability of advanced machinery has made it easier for farmers to process and prepare peanuts for various applications, such as peanut snacks, peanut butter, and other peanut-based products.

Peanut Kernel (Shelled Peanut with Skin):

For peanuts used in various food products, including confectioneries, baked goods, and culinary dishes, the precise removal of the outer skin is crucial. Peanut shelling machines facilitate this process, resulting in uniform, clean, and ready-to-use peanut kernels.

Peanut Shells:

Even the peanut shells do not go to waste. They can be used as animal feed, biomass fuel, or in the production of bio-compost and other agricultural applications. Properly shelled peanuts ensure that the peanut shells are free from excessive contamination, contributing to their value as by-products.

As the demand for peanut products continues to grow, the modernization of peanut shelling machines becomes an inevitable and significant development. These machines play a crucial role in enhancing labor productivity, reducing labor intensity, and advancing the science and technology of peanut processing. With continued support and innovation, the future of peanut shelling machines is promising, ensuring a sustainable and prosperous peanut industry.