Design and fabrication of peanut shelling machine

With the continuous development of agricultural mechanization, the demand for agricultural products processing equipment is increasing. As an efficient and practical agricultural equipment, peanut shelling machine plays an important role in agricultural production. This paper will briefly introduce the design concept, structural characteristics and manufacturing technology of peanut sheller.

Peanut sheller design concept

The design of peanut shelling machine aims at improving efficiency and reducing labor intensity, while paying attention to the stability of equipment and the protection of peanut kernels. In the design process, it is necessary to comprehensively consider the physical characteristics of peanuts, such as the hardness of the shell and the fragility of the kernel, to ensure that the shelling process is efficient and does not damage the peanut kernel. In addition, the equipment also needs to meet the requirements of easy operation, easy maintenance, energy saving and environmental protection, so as to adapt to the development trend of modern agriculture.

Structural characteristics of peanut shelling machine

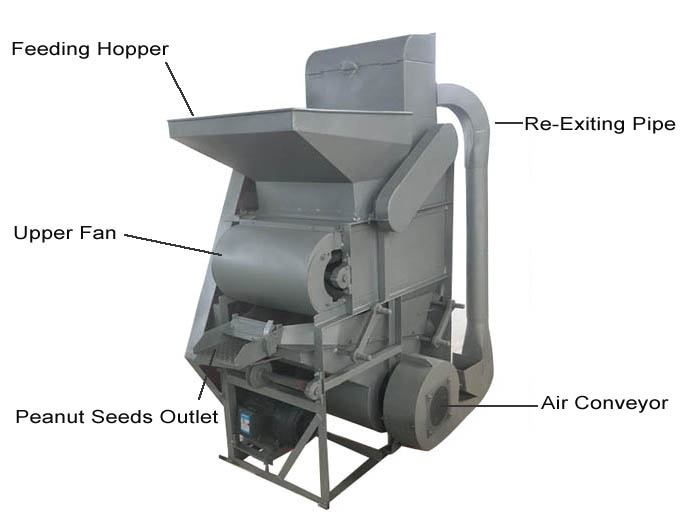

Peanut shelling machine usually consists of feed inlet, shelling device, screening device and discharge port.

1. Feed inlet: Designed as a spacious and smooth structure, to ensure that peanuts can enter the peanut sheller evenly and avoid blockage.

2. Shelling device: One of the core components, usually adopts drum-type or hammer-type structure, and realizes the separation of peanut shells and kernels by rotating or tapping. Wear resistance and strength should be paid attention to in material selection to prolong service life.

3. Screening device: It is used to separate shelled peanut kernels and shells, and the aperture of the screen should be designed reasonably according to the size of peanuts to ensure the separation effect.

4. Discharge port: It is divided into kernel outlet and shell outlet, and fluency should be considered in design to avoid mixing or blockage.

Peanut shelling machine manufacturing process

The fabrication process of peanut sheller includes parts processing, assembly and debugging. In the process of machining, the dimensional accuracy and material quality should be strictly controlled to ensure the equipment performance. At the same time, in the assembly process, it is necessary to ensure that all components are firmly connected, and the whole machine is debugged to ensure smooth operation, low noise and high efficiency. In addition, in order to meet the needs of users of different scales, we can provide equipment of various models and specifications.

The design and fabrication of peanut shelling machine is an important subject in the field of agricultural machinery, and its performance directly affects the processing efficiency and economic benefits of peanut industry. By continuously optimizing the design and improving the fabrication process, the future peanut sheller will be more efficient and intelligent, which will provide strong support for the development of agricultural modernization.