Different working principles of dry type peanut peeling machine and wet type peanut peeling machine

In order to obtain complete peanut kernels in peanut processing, the first step is to peel peanuts, and the peanut peeling machine is used here. Peanut peeling machine can be divided into dry type peanut peeling machine and wet type peanut peeling machine.

Dry type peanut peeling machine

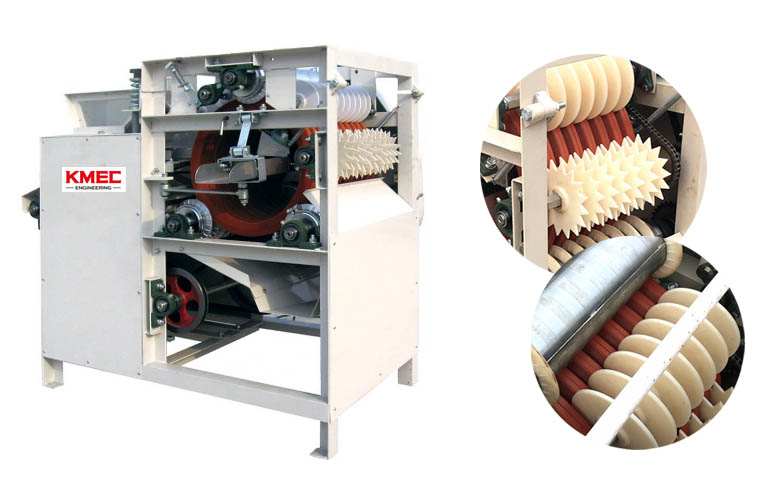

The dry type peanut peeling machine consists of a peeling machine, a rack and a suction peeling device. It has the advantages of stable performance, long service life, good peeling effect, high productivity, low half-grain rate and so on, and can be used in combination with multiple sets.

Dry type peanut peeling machine adopts the working principle of differential rolling friction transmission. When the moisture content of the roasted peanuts is less than 5%, the peanuts are peeled, and then the peanuts are sucked away by the exhaust system, so that the whole peanuts and half peanuts are separated one by one.

Dry type peanut peeling machine is an ideal equipment for peeling red skin of peanuts, with compact structure and stable operation. After peanuts are put into the hopper, they automatically enter the peeling room composed of two sets of friction rollers to remove the skin of peanuts and become white and intact peanuts. Suitable for producing peanut candy, peanut butter, peanut milk, peanut cakes and other series of foods.

Wet type peanut peeling machine

–> Chad customer repurchased a peanut peeling machine

Wet type peanut peeling machine consists of power device (including motor, belt pulley, belt, bearing, etc.), frame, feed hopper, peeling roller (steel roller or sand roller), peeling fan, etc. Peeling of peanuts is carried out in a way of differential rolling and peeling of rollers, which can be used in combination with multiple sets and is suitable for processing various specifications of peanuts. It is the early peeling step of processing various peanut products such as coated peanuts, cocoa peanuts and milky white peanuts.

When the wet type peanut peeler machine works, the peanuts soaked in cold and hot water are poured into the hopper of the machine, and the peanuts enter the rotating rubber wheel fixed by three power rollers through vibration, and the peeling effect is achieved through the manual twisting wheel under the action of the induction strip and the feeding wheel, and then the peeled peanuts are pressed into the discharging hopper by the discharging wheel and discharged from the discharging hopper, and the skins are thrown out through the peeling wheel.

The wet type peanut peeling machine has high peeling rate, and the peeled peanuts are not broken, with white color and protein invariance. While peeling, the skin and kernel are automatically separated. The equipment has the characteristics of small size, low energy consumption and easy operation, and has a wide range of applications. At the same time, it can be used for wet peeling of almonds and beans.

The structure, working principle and application scope of dry type peanut peeling machine and wet type peanut peeling machine are different. When choosing peanut peeler machine, you need to decide whether to buy dry type peanut peeling machine or wet type one according to your own needs.