How to improve the working efficiency of peanut butter filling machine

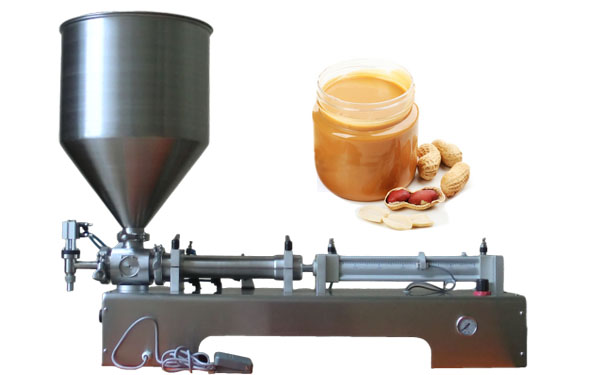

Peanut butter filling machine is one of the indispensable equipment in modern food processing production line. Its main function is to accurately fill peanut butter into containers to ensure the quality, hygiene and safety of products. However, with the increase of market demand and the intensification of competition, it is particularly important to improve the working efficiency of peanut butter filling machine.

This article will introduce some methods to improve the working efficiency of peanut butter filling machine.

First of all, reasonable arrangement of production plan is the key to improve the working efficiency of peanut butter filling machine. According to the market demand and order quantity, make a reasonable production plan and arrange the production time and output reasonably. Avoid overproduction or short supply, and ensure that the peanut butter filling machine always runs efficiently.

Secondly, optimizing the equipment operation process is also an important measure to improve the working efficiency of peanut butter filling machine. By analyzing and improving the equipment operation flow, unnecessary operation steps and time waste are reduced. For example, packaging containers with different specifications can be matched with peanut butter filling machines to reduce the time for adjusting and replacing equipment. At the same time, train operators, improve their operating skills and efficiency, and ensure that the equipment can run in the best state.

Thirdly, regular maintenance of peanut butter filling machine is also an important link to improve work efficiency. Regularly check the normal operation of all parts of the equipment, and replace the seriously worn parts in time to ensure the stability and reliability of the equipment. At the same time, clean the inside and outside of the equipment regularly to prevent impurities and pollutants from affecting the performance of the equipment. Only by keeping the equipment in good condition can it work efficiently.

In addition, the working efficiency of peanut butter filling machine can also be improved with the help of automation technology. By introducing automatic control system and sensor, the automatic operation and monitoring of equipment are realized. Automation technology can greatly reduce manual intervention and operational errors, and improve production efficiency and product quality. At the same time, automation technology can also realize remote monitoring and fault diagnosis of equipment, find and solve problems in time and reduce downtime.

Finally, maintaining a good cooperative relationship with suppliers is also the key to improve the working efficiency of peanut butter filling machine. Establish long-term and stable cooperative relations with suppliers, keep abreast of new products and technologies, and update and improve them in time. Suppliers can provide professional technical support and after-sales service, solve the problems encountered in the use of equipment and ensure the normal operation of equipment.

In a word, improving the working efficiency of peanut butter filling machine needs to start from many aspects. The effective measures such as reasonable arrangement of production plan, optimization of equipment operation process, regular maintenance, using automation technology and maintaining good cooperation with suppliers can effectively improve the work efficiency and product quality of equipment.