Notes on maintenance of peanut peeling machine

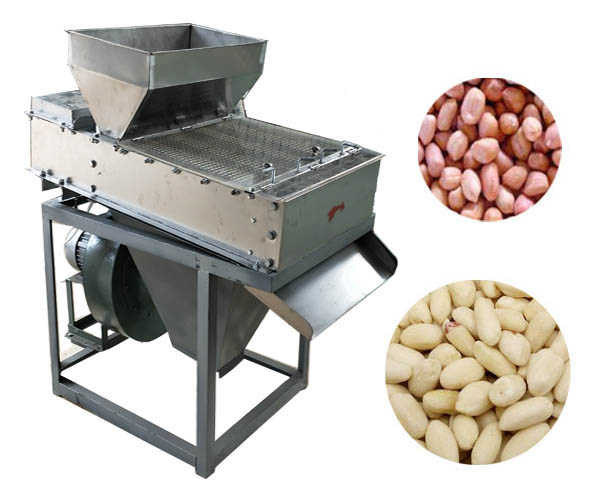

Peanut peeling machine is a professional equipment used to remove the red coat of peanut, which is widely used in peanut product processing. Peanut peeling machine will inevitably fail after long-term use. Once it fails, it is necessary to repair the machine in time. During the maintenance of peanut peeling machine, there are some matters that need our attention. Let’s take a look at them today.

Main notes on the maintenance of peanut peeling machine:

First, prevent crush injury。

In the process of maintaining the peanut peeler machine, the tires of the peanut peeler machine are firmly plugged with triangular wood. And after jacking the peanut peeling machine with a jack, it should also be supported by supporting things; Before loosening the jack, pay attention to whether there are people and obstacles around; Overhauling the pipeline of the hydraulic compartment can only be carried out after the inclined peeling compartment is firmly supported.

Second, prevent burns.

When checking the running starter, you should avoid being scalded by high-temperature gas, especially the gas discharged from the exhaust pipe. If the water temperature of the water tank is very high, don’t rush to open the lid with your hands to avoid being scalded by boiling water.

Third, anti-corrosion.

The electrolyte of storage battery should be prepared by using ceramic or glass containers. When checking the height and density of electrolyte, don’t let the electrolyte splash on clothes or skin.

Fourth, prevent poisoning.

During the maintenance period, the starter needs to be started frequently, and gas welding and electric welding may be carried out frequently sometimes. Therefore, it is necessary to keep the air circulation in the maintenance environment to avoid slow poisoning.

Fifth, oil prevention.

The oil tank and oil drum shall be thoroughly cleaned before welding repair, and welding shall be carried out only after the inner cavity is confirmed to be free of oil and gas. Besides, mars should be avoided beside the battery to avoid the accumulation of hydrogen and oxygen from overflowing from the battery.

Sixth, prevent electric shock.

Electrical equipment must be firmly grounded, and switching equipment must be higher than the head. Wire aging or damage should be replaced in time to avoid electric shock.

Seven, fire prevention.

Open flame is not allowed when maintaining gasoline engine. The gasoline basin shall not be put aside near the grinder. Cotton yarn and rags stained with waste oil shall be properly disposed of in time and shall not be littered.

After the maintenance of the peanut peeling machine is completed, it is necessary to clean the appearance of the machine, and the machine should be powered on to see if it can work normally, and then the operator should start it for trial use. If problems are found, they must be solved in time to avoid leaving danger. Check and clean the working site to see if there are any missing screws, spare parts and things, and fill in the maintenance log for future reference. If you want to know more information about peanut peeler machine, please contact us!