Problems needing attention in using peanut peeling machine in winter

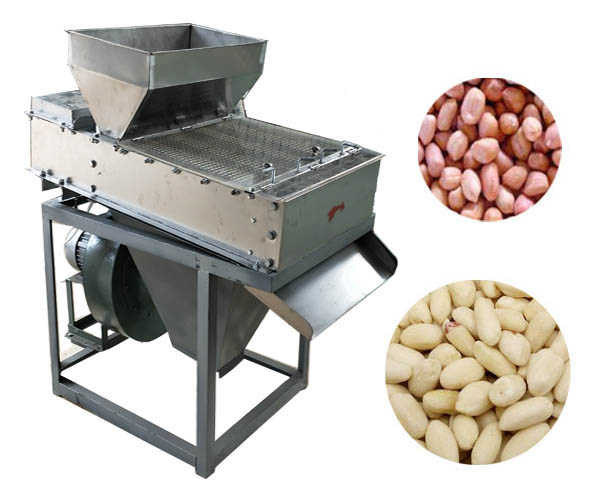

Peanut peeling machine is a professional equipment to remove the red skin of peanut. The appearance of peanut peeling machine greatly improves the efficiency of peanut red skin removal. Peanuts usually need to be peeled when they are deeply processed. When peanut is used to make oil, the purpose of peeling is to improve the oil yield and the quality of crude oil and the cake, which is beneficial to the subsequent processes such as embryo rolling and the comprehensive utilization of peel. When peanut is used to make peanut butter, peeling is for the dual purpose of beauty and better taste. The traditional peeling is manual peeling, which is not only easy to get tired and injured, but also has low efficiency. Therefore, farmers in peanut producing areas urgently require peanut machines to replace manual peeling, and the emergence of peanut peeling machine has liberated farmers from heavy manual labor.

There are many problems that need attention when peanut peeler machine is used, especially in winter, we should pay more attention to the use of the machine.

The main problems that should be paid attention to when using peanut peeling machine in winter are as follows:

1. The peanut peeling machine needs to be warmed up and preheated before it officially works. When it is started at low temperature, due to the high viscosity of engine oil, the lubricating oil will be insufficient in a short time and cannot be distributed all over the lubricating points.

2. Due to the influence of low temperature, the application facilities of peanut peeler machine will be changed in different degrees in winter, which will increase the damage frequency of the accessories of the equipment . Therefore, in order to ensure its normal working process, it is necessary to carry out necessary equipment inspection before operation.

3. Low temperature will increase the viscosity of the lubricating oil of the machine , and it is easy to wear the accessories, so it is necessary to change the lubricating oil type in time.

4. Clean up in time when the operation is completed. Prevent dust and other sundries from invading.

The above are the matters needing attention when the peanut peeling machine is used in winter, and we must pay enough attention to it. Only in this way, can we guarantee the good performance of the equipment, reduce the frequency of faults and reduce the cost and economic loss of machinery maintenance. The reduction of machine failure rate can not only help us peel peanuts better, but also prolong the service life of peanut peeling machine and create greater economic benefits.