Regular cleaning of peanut butter filling machine is very important

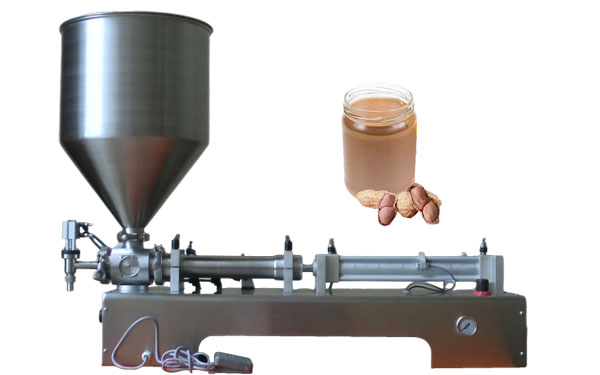

Peanut butter filling machine is a common equipment in food processing industry. In order to ensure product quality and production safety, regular cleaning is very important.

The following will introduce the cleaning steps and precautions of peanut butter filling machine.

First of all, it is necessary to turn off the power supply of the peanut butter filling machine before cleaning, and clean up the peanut butter and other materials remaining inside the machine. Special tools and detergents can be used for cleaning to ensure the thorough removal of residues.

Secondly, remove the easily contaminated parts of the peanut butter filling machine, such as pipes, valves, filling heads, etc., and put them into the cleaning tank for soaking. In the process of soaking, we can use a brush or a water gun to clean the dirt attached to the surface to ensure thorough cleaning.

Thirdly, clean the internal structure of peanut butter filling machine. First, spray and wipe the internal surface with detergent and clean water to ensure the removal of grease and dirt. Then, rinse with clean water and dry the inner surface with a clean cloth.

Fourthly, it is necessary to clean and inspect the transmission system and electrical components of peanut butter filling machine. For the transmission system, cleaning agent can be used to wipe the transmission chain and gear to ensure their surfaces are clean. For electrical components, it is necessary to pay attention to avoid water or detergent from entering the electric control box to avoid damage.

Finally, the peanut butter filling machine needs to be disinfected after cleaning. Food-grade disinfectants can be used to spray and soak all easily contaminated parts and internal surfaces to ensure thorough disinfection. After disinfection, the peanut butter filling machine needs to be washed with clear water and dried.

When cleaning the peanut butter filling machine, we should pay attention to the following points:

- Use special detergents and disinfectants to avoid affecting food safety.

- During cleaning, pay attention to personal safety protection and avoid contact with chemicals and hot water.

- After cleaning, the peanut butter filling machine should be thoroughly inspected to ensure that the equipment is intact.

To sum up, the regular cleaning of peanut butter filling machine is an important link to ensure the hygiene and safety of products, which requires operators to operate in strict accordance with the operating rules. Only by doing a good job of cleaning can we ensure the production of high-quality peanut butter products.