The correct use of wet type peanut peeling machine

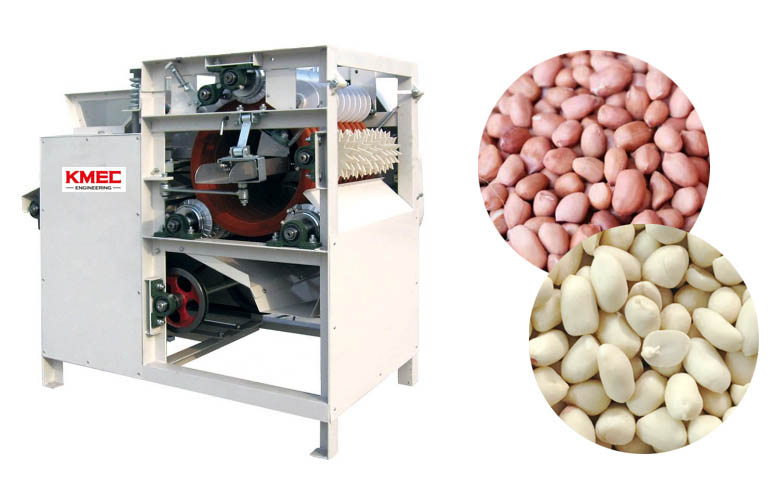

The wet type peanut peeling machine is a highly efficient piece of equipment designed to remove the red skin from soaked peanuts. This innovative machine utilizes a wet peeling process, ensuring the peanut kernels remain intact and undamaged during the peeling procedure. Proper usage of this machine is crucial to achieve optimal peeling results, ensuring bright, unblemished peanut kernels while efficiently separating the peel for various applications.

How to use peanut peeling machine correctly:

Appropriate Installation

Before operating the wet type peanut peeling machine, ensure that it is installed on a flat, hard ground with adequate water supply and drainage facilities. This placement is essential as the machine utilizes a wet process, requiring a consistent water supply to facilitate the peeling operation efficiently. Furthermore, a stable foundation prevents vibrations and movement during operation, promoting safety and minimizing damage.

Thorough Inspection

Before each use, perform a comprehensive inspection to ensure the machine’s optimal performance. Check all equipment bolts and motor fixing parts to ensure they are tightly secured. Loose components can lead to malfunctions, accidents, or reduced peeling efficiency. Paying attention to maintenance and repairs will extend the machine’s lifespan and maintain its high peeling rate.

Verify Motor Direction

Prior to feeding the peanuts into the machine, turn on the power supply for a trial run to check if the motor is rotating in the correct direction. The motor should rotate in a way that facilitates efficient peeling without causing unnecessary damage to the peanuts. This step is vital to avoid potential accidents and to ensure the peanuts are processed correctly.

Lubrication

Regular lubrication is crucial for the proper functioning of the wet type peanut peeling machine. Apply the specified grade lubricating oil to all relevant parts that require lubrication. Adequate lubrication reduces friction and wear, enhancing the machine’s efficiency and extending its operational life.

Start the Peeling Process

Once you have thoroughly inspected, verified, and lubricated the machine, you can proceed to start the peeling process. Pour the soaked peanuts into the machine’s hopper, and they will enter the rotating rubber wheel fixed by three power rollers through vibration. The peanut skins will be cut by the blades on the tool rest as the peanuts move forward due to the action of the guide strip and feeding wheel.

Harvesting the Result

As the peanuts are peeled, they will be pressed into the discharging hopper and then discharged from it. The skin is separated and thrown out by the peeling wheel. The peeled peanuts obtained from this process are not broken, retain their natural color, and maintain their protein content.

The wet type peanut peeling machine is an excellent tool for efficiently removing peanut skins while preserving the integrity of the kernels. By following the correct procedures and maintenance guidelines, users can achieve high peeling rates, bright and unblemished peanut kernels, and an automated peel separation process. This versatile machine finds applications in various products such as fried peanuts, almond pickles, soybean protein milk powder, and canned almonds, among others. Mastering the art of using the wet type peanut peeling machine ensures its longevity and sustained benefits for peanut processing operations.