What determines the filling accuracy of peanut butter filling machine?

As a popular food, the filling process of peanut butter is very important. Filling accuracy not only affects product quality and consumer satisfaction, but also directly affects production cost and efficiency. So, what factors determine the filling accuracy of peanut butter filling machine?

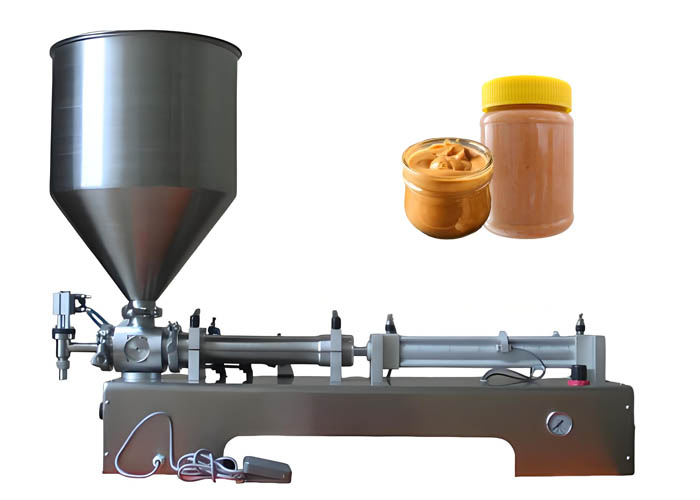

First of all, the structural design of the peanut butter filling machine has a great influence on the filling accuracy. High-precision peanut butter filling machines usually have a precise metering system and a stable mechanical structure. These designs can ensure that peanut butter can be accurately distributed to each container during the filling process without excessive or insufficient phenomenon.

Secondly, the type of technology used in the peanut butter filling machine is also one of the key factors to determine the accuracy. At present, the common filling technologies in the market include piston type, screw type and flowmeter type. Different types of technology have different adaptability to peanut butter with high viscosity. For example, piston peanut butter filling machine can usually provide high filling accuracy because of its good sealing and pressure control.

Thirdly, the filling environment and operating conditions will also affect the filling accuracy. Environmental factors such as temperature and humidity may change the fluidity of peanut butter, thus affecting the filling process. In addition, the skill level of operators and the standardization of operation processes will also have an impact on the final filling accuracy. Therefore, training qualified operators and formulating strict operating procedures are important means to improve filling accuracy.

Furthermore, the maintenance of equipment is also a factor that cannot be ignored. Regular inspection and maintenance of the peanut butter filling machine can ensure that it is always in the best working condition, thus ensuring the filling accuracy. If worn or faulty parts are not replaced or repaired in time, it may lead to inaccurate filling.

Finally, the quality and consistency of raw materials also affect the filling accuracy to some extent. If the consistency and particle size of peanut butter are inconsistent, the flow rate will be unstable during filling. Therefore, selecting high-quality and consistent raw materials is an important prerequisite to ensure the filling accuracy.

To sum up, the filling accuracy of peanut butter filling machine is determined by many factors, including structure design, technical type, filling environment, equipment maintenance and raw material quality. In order to achieve the best filling effect, enterprises need to comprehensively consider these factors and take corresponding measures to optimize, thus improving product quality and market competitiveness.