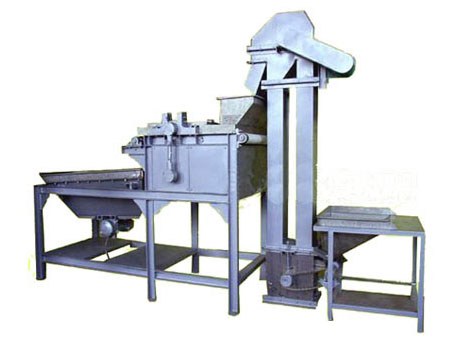

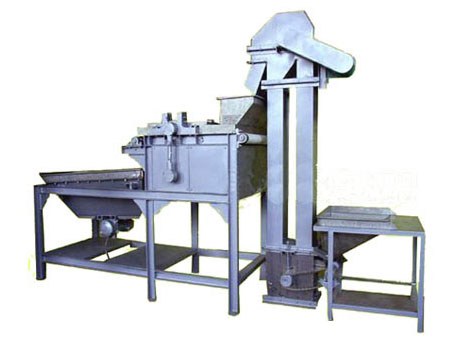

Peanut Chopping Machine, Commercial Nut Crusher

Peanut chopping machine is also called nut crusher. The machine is used to cut the nuts such as peanut, almond nut, hazelnut, etc. into small pieces. It’s widely used in the food processing industry such as candy, pastry, peanut brittle, etc.

Product introduction

The Versatile Nut Crusher

The multipurpose peanut chopping machine is more than just a tool; it’s a breakthrough in food processing technology. Engineered to perfection, this machine employs a combination of reciprocating cutter chopping and rolling cage classification, resulting in uniform and precise nut chopping. It has proven itself as the go-to equipment for crushing peanuts, offering distinct advantages that include oil leakage prevention, standardized classification, high-quality finished products, and environmental friendliness. Its scope extends beyond peanuts, encompassing hazelnuts, almonds, beans, wheat, and more, making it an indispensable asset for various granular or banding feedstock.

Advantages of the Peanut Chopping Machine

Oil Leakage Prevention: One of the primary concerns when processing nuts is oil leakage, which can adversely affect the taste and quality of the final product. The peanut chopping machine overcomes this challenge, ensuring that the chopped nuts remain free from oil contamination.

Standardized Classification: Consistency is key in food production. The machine’s advanced classification process ensures that each chopped nut piece adheres to the same size, allowing manufacturers to create uniform food products.

High-Quality Output: The precision cutting mechanism guarantees high-quality chopped nuts, meeting the standards expected by consumers and industries alike.

Environmental Friendliness: In an era where sustainability is paramount, the machine’s efficiency minimizes wastage and pollution, contributing to a more environmentally conscious food processing landscape.

Versatility: While its name may suggest a focus solely on peanuts, the machine’s capabilities span a wide range of nuts and feedstock, making it a versatile asset for food manufacturers.

Working Mechanism of Peanut Chopping Machine

At the heart of the peanut chopping machine’s efficiency lies its intricate working mechanism. The process begins with elevating shelled peanuts into the cutting chamber via an elevator. The crushing process follows a two-tiered classification. In the first level, half-kernel peanuts are reduced to larger granules, setting the stage for the second cut. In the second cut, these larger granules are further refined into fine grains, ensuring an unparalleled consistency in the final product.

A pivotal aspect of the machine’s functionality is its vibration sifter, which classifies the falling peanuts into four distinct sizes. This ensures that the chopped nuts are uniform in size, catering to the demands of the culinary industry where precision matters. By adhering to such rigorous classification standards, the peanut chopping machine guarantees a high-quality output that meets the requirements of diverse applications.

This machine has emerged as an essential tool in the hands of food manufacturers. As technology continues to advance, it is innovations like the peanut chopping machine that keep the food industry moving forward, catering to both consumer demands and the need for efficient, high-quality food production.