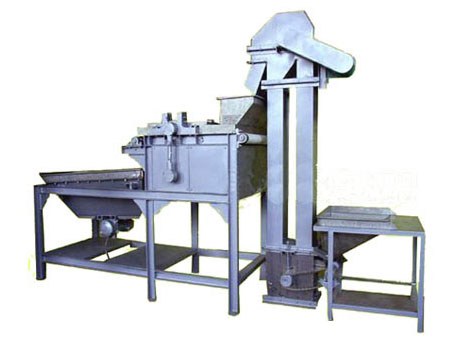

Electric wheat flour mill, commercial grain mill machine for sale

Model: KM-812;

Power supply: 1.5kw;

Dimension: 55*25*75cm;

Weight: 38kg;

This grain milling machine is popular in homes, drugstores, food processing plants.It is widely used in pharmaceutical, food,chemical industry materials crushed. The machine can grind all kinds of food and medicines into 50~200 meshes.

Product introduction

Commercial grain mill machine, we can also call it electric wheat flour mill, is an equipment widely used to process all kinds of oily material , fiber/herb material, dry material, hard material, sugar material, and so on into powder. Dry medicinal materials, including almond, tuckahoe, red jujube,euryale seed,medlar, mastic, dodder seed,angelica and so on, together with various grains, such us sesame, walnut, rice, black rice, soy, mung bean, peanut, lotus seed, corn, broomcorn, barley, buckwheat, oat, etc can all use this electric wheat flour mill to produce flour.

Specification of grain mill:

Voltage: 220V

Power supply: 1.5kw

Velocity of rotation: 1420r/min

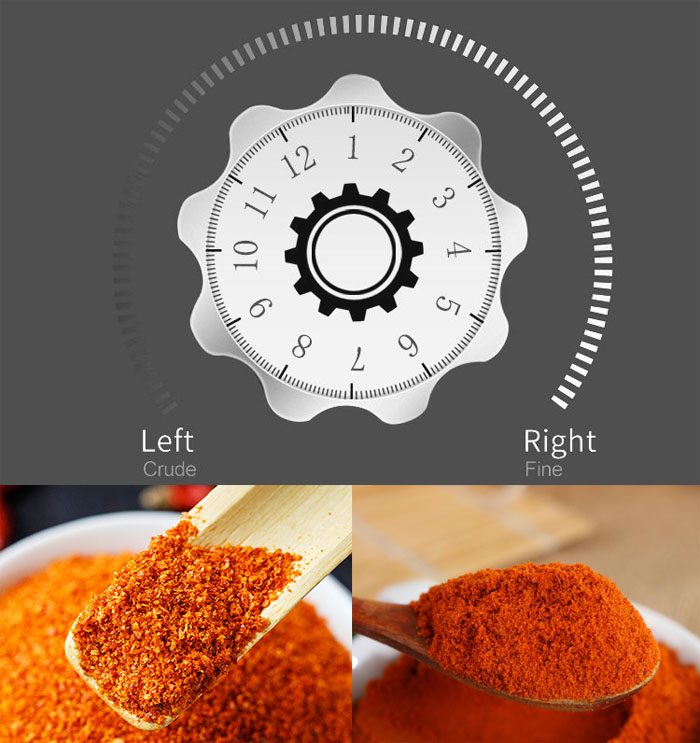

Fineness: 20-200mesh

Dimension: 552575cm

Weight: 38kg

This electric wheat flour mill is widely used in food industries, processing plants, markets, farms, and also homes, it can meet the requirements of most of users. The main reasons for the larger use grain mill machine is that it helps to grind salubrious wheat flour. And use these machines to grind wheat flour is helping to hold its dietary worth and goodness.

Type 860 commercial grain mill machine is a hot sale equipment in the market, based on its successful sale experience, type 812 small stainless steel grain mill come into being. Here are the features of type 812 small stainless steel grain mill:

1. It is specialized in milling whole grains.

2. The volume of type 812 is smaller than type 860 .

3. The mill blade diameter is 120mm.

4. Equipped with 1.5kw sheer copper motor, professionally customized by the factory, so the drive power is strong.

5. The yield may reach 10-30 kg/h as well.

6. Type 812 can mill kinds of grains, Chinese herbal medicine etc materials into uniform powder with 50-200 mesh.

7. It can meet the use requirements of most users, and it is an ideal mill machine for kinds of small mill workshop.

When the motor of grain mill runs, the connecting shaft and the milling disc sleeving on the connecting shaft will rotate together. After pending milled materials go into casing of milling powder from the hopper, mill disc brings materials to the middle of two milling blades. After the materials go across two milling blades, the finished materials are thrown everywhere under the centrifugal force. At the same time, bringing down by the scraping plate installed on the grinding disc, and comes out from the feed downpipe.

Maintenance of grain mill:

1. Regularly check the bearings and replace the high-speed butter to ensure the normal operation of the machine. Frequently check the wearing parts. If there is any serious wear, replace it in time.

2. When the machine is in use, if the spindle speed is gradually decreasing, you should adjust the motor downwards. Then the machine can reach the specified speed. If there is an abnormality, the machine should be shut down for inspection.

3. Metal materials, such as nails, iron blocks, etc, are strictly prohibited from flowing into the inside of the machine when it is turned on. After the work is over, you must clean the residual materials in all parts of the machine. If the machine is out of use for a long time, the machine must be wiped clean and covered with a tarp cloth.

Because of the features of this electric wheat flour mill, it can be used as a domestic flour mill or as a commercial one. This grain mill can produce various refined grains flour in a particular short time, its a good choice for many users.