As the consumption of edible oil is increasing year after year with the improvement of people’s living standard, oil milling has become a fast growing industrial activity all over the world. With the advent of more and more manufacturers of oil mill machinery who help to design complete oil mill plant based on specific requirements of the customer, a worldwide revolution in oil manufacturing industry has been propelled. If you are also considering setting up a small scale oil mill that can not only satisfy your daily oil consumption, but also cater to regional markets to make some profit, you have got the right place!

Oil Mill Supplier

As one of the leading manufacturers and exporters of oil mill plant and oil mill machinery with more than 20 years of experience, we offer a wide range of durable and cost-effective oil mill plant and oil mill machinery with high working efficiency for the oil mill industries. Nearly all of the oil seeds and nuts can be processed with the oil mill plant. The crushing capacity of the oil mill varies from 3 tons to 100 tons per day to meet different production requirements of customers. With constant innovation in technology and strict quality measurement system, we assure to deliver the best oil mill plant for customers all over the world.

Main Equipment of the Oil Mill

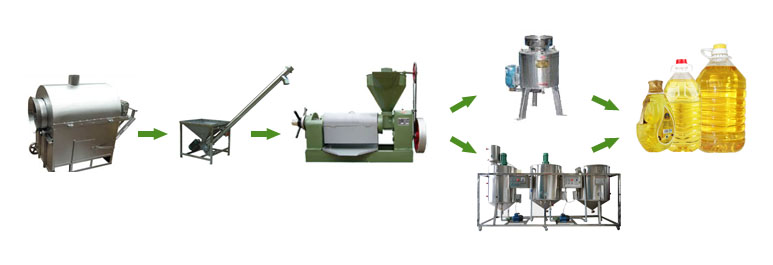

Oil mill plant can be divided into different scales, including small scale, medium scale and large scale for different processing purposes. A complete oil mill plant consists of various sections, such as seed processing section, oil extraction section and oil filtration section. Therefore, different oil processing equipment should be used according to different plant seeds you are going to process. Among all the processing equipment of the complete oil mill plant, oil press is the vital and indispensable part. Users can use the common peanut oil press and a filter press or an integrated oil mill plant to extract and filter oil. A peanut sheller is necessary if you want to produce peanut oil, while if you are going to make cotton seed oil, you should take the disc huller into consideration. We can also customize the oil mill plant according to the raw materials and production capacity of customers to provide the most professional oil mill plant that can satisfy all of the oil making needs. The oil mill plant produced by our company can be used to process various kinds of oil seeds, such as peanut kernels, rapeseed, cotton seeds, sunflower seeds, corn germ, palm kernels, sesame seeds, etc.

Oil mill plant can be divided into different scales, including small scale, medium scale and large scale for different processing purposes. A complete oil mill plant consists of various sections, such as seed processing section, oil extraction section and oil filtration section. Therefore, different oil processing equipment should be used according to different plant seeds you are going to process. Among all the processing equipment of the complete oil mill plant, oil press is the vital and indispensable part. Users can use the common peanut oil press and a filter press or an integrated oil mill plant to extract and filter oil. A peanut sheller is necessary if you want to produce peanut oil, while if you are going to make cotton seed oil, you should take the disc huller into consideration. We can also customize the oil mill plant according to the raw materials and production capacity of customers to provide the most professional oil mill plant that can satisfy all of the oil making needs. The oil mill plant produced by our company can be used to process various kinds of oil seeds, such as peanut kernels, rapeseed, cotton seeds, sunflower seeds, corn germ, palm kernels, sesame seeds, etc.

Oil Mill Projects

So far, we have helped to set up a great number of successful mini oil mill projects in domestic and overseas. The following is a list of some of these oil mill projects. If you are also interested in our mini oil mill plant, welcome to get in touch with us without hesitation, we are always at your service!

Compared to large scale oil mill with large capacities and caters to regional market with established brands and different varieties, mini oil mill is the oil processing plant or even small assembly line with small capacity that caters to the local market. Therefore, it can be set up in the village to produce pure, fresh and natural oil for the villagers with their own oil seeds that greatly saves the transport expense for carrying oil seeds to the city and bringing oil from the city. The application of mini oil mill greatly promote the development of rural areas, since more wealth and self employment jobs are created with the establishment of mini oil mill. A series of oil mill machinery can be connected in the mini oil mill in order to increase the oil production efficiency and get higher oil yield. These oil mill machinery can be used separately as well. The whole oil mill plant is easy to operate, install and commission. Oil cakes produced in the production of oil mill plant can also be used as the feed for the poultry, which would promote the development of rural animal husbandry as well.