The screw oil press machine is an advanced screw type oil press machine which is widely used in pressing oil from vegetable oil seed, such as peanuts, rapeseeds, sesame seeds, soybeans, cotton seeds, tea seeds, tung tree seeds, sunflower seeds, palm seeds, etc.

Specifications of oil press machine

| Model | Capacity(kg/h) | Power(kw) | Net weight(kg) | Size:(mm) |

| 6YL-68 | 40 | 5.5 | 140 | 880*440*765 |

| 6YL-80 | 80-125 | 5.5 | 330 | 1320*540*1020 |

| 6YL-95 | 160-200 | 7.5 | 520 | 1910*610*765 |

| 6YL-100 | 160-200 | 7.5 | 480 | 1860*550*695 |

| 6YL-120 | 200-300 | 15 | 680 | 1970*700*780 |

| 6YL-130 | 375-500 | 18.5 | 820 | 2320*700*780 |

Oil crops that can be pressed with screw oil press:

The advantages of screw oil press:

1, Labor saving: 60% of the labor force can be saved with the same output, for only 1 or 2 people are needed for the production.

2, Wide range of application: the screw oil press has multi-functions and more than 30 kinds of oil-bearing crops like peanut, sesame, sesame, rapeseed, sunflower, cottonseed and soybean can be pressed with the oil press machine. Multistage press and single press can be achieved for complete pressing.

4, Pure oil: residues can be removed with the vacuum filter to ensure the pure of oil.

5, Small space occupation: 10-20 square meters is enough for the oil mill.

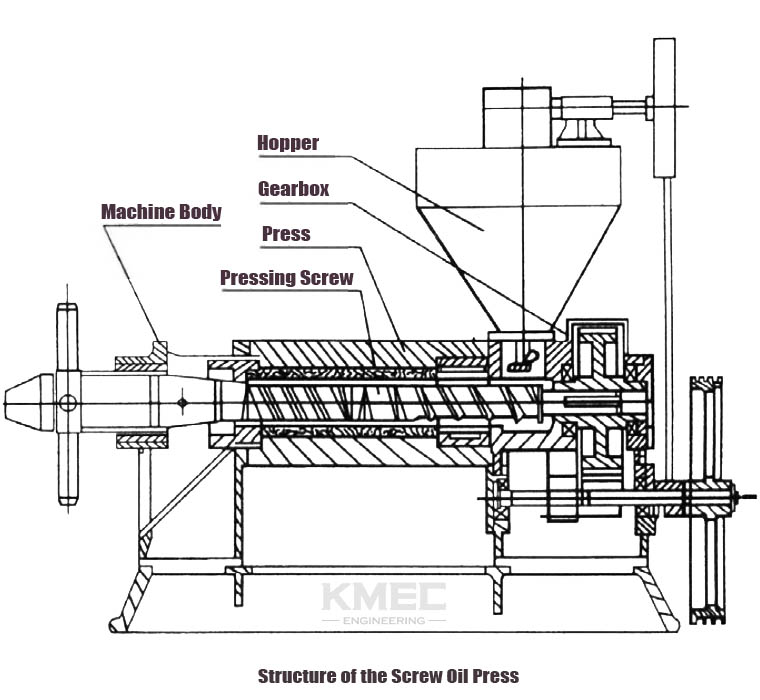

Structure of the Screw Oil Press

The screw oil press machine is mainly composed of the hopper,gearbox,press,pressing screw and machine body, etc. As the key part of the oil press machine, the pressing chamber of screw oil press consists of the pressing cage and a screw shaft rotating in the cage. The motor, diesel engine or electrical control cabinet can be equipped in the screw oil press according to your own needs. An electric cabinet can be used to control the whole working procedure of oil press machine.

Maintenance of screw oil press:

1.Check the lubrication condition of screw oil press every 50 hours. The oil bottle on the gear box can not be short of oil. Adjust the screw bearing from the screw holes with the squeezing screw shaft. Add butter per shift and prohibit dry grinding.

2. Prevent dust and other impurities from falling in each lubricating part and check the oil quality of the reducer every year. Once found the deterioration of oil, the operator should replace all the oil.

3. When the press quality reduces or the discharging of cake or oil is not normal, the operator should remove the screw nut and check the wear condition of the pressing screw, pressing bar and the cake outlet ring. The wear parts should be replaced timely.

4. When the production is finished, the residual oil press cakes should be cleared. Clean the screw oil press and remove the dust and grease on the machine surface.

5. For the long time storage of the screw oil press machine, the operator should make a complete maintenance and unpick, wash and oil the pressing screw, pressing bar and cake outlet ring, then place them in a dry place.

KMEC is the earliest manufacturer to develop, design and produce the screw oil press machine in China with many years of production experience, first class production equipment and standard finished products. Welcome customers all over the world to consult and purchase our products.