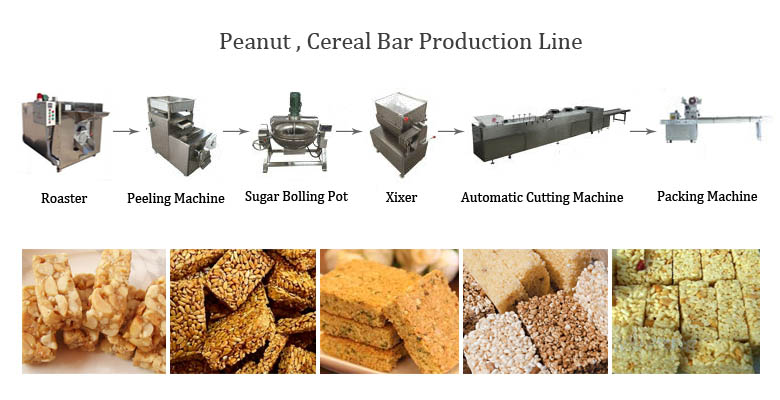

The peanut brittle machine adopts automatic PLC control. It mainly consists of material feeding, rolling, cooling, cutting and conveying. The peanut brittle machine can be used to make cereal bar, granola bar, muesli bar, nuts bar, seeds bar, energy bar, puffed rice bar, etc. It is an essential equipment in peanut brittle and cereal bar production lines.

Performance and structural characteristics

1. Adopt double frequency conversion control, leveling the cuttings in once time.

2. The length of the cooling conveying belt can be changed and cooling fans can be equipped as required so as to enhance the cooling effect.

3. Advanced frequency control of motor speed can meet your needs in different products.

4. Automatic cutting saves time and labor in production.

Operation point of peanut brittle machine

1.The operation of peanut brittle machine should be arranged by full-time personnel.

2.Turn off the power supply and wear gloves before changing the mould of peanut brittle machine to avoid hurting your hands.

3.The machine should be kept clean and tidy. Waste material on the circular knife must be cleaned every shift.

4. Prevent water infiltration on electrical components and computer touch screen.

The peanut brittle machine is widely used for molding and cutting peanut brittles and cereals in the same size automatically. It has large output and easy operation. Different moulds can be used to produce various sorts of products.