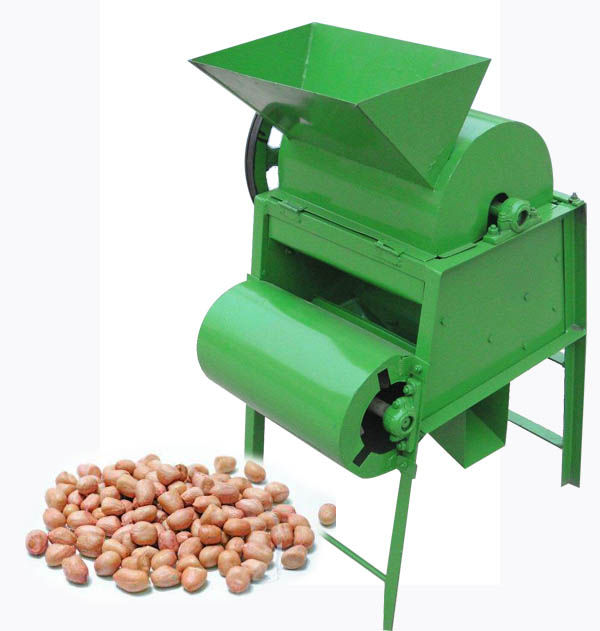

BK-200 Peanut Shelling Machine

Capacity: 200KG/H

The small peanut shelling machine can adapt to different varieties of peanut shelling, due to its small size, easy operation,

BK-700 Peanut Shelling Machine

Capacity: 500-700kgKG/H

This peanut shelling machine has features as good shelling effect, small size, convenient to move and save human power. Simple structure, easy to operate

BK-3500 Peanut Shelling Machine

Capacity: 3500kgKG/H

It is the best-selling product of our company in recent years. The main features of the peanut sheller is that the peanuts processed are with low breakage.

BK-3500B Peanut Shelling & Cleaning machine

Capacity: 3500kgKG/H

The peanut sheller and cleaning machine has three parts: the first part is peanut cleaning machine, used for removing stones and impurities in the peanuts

BK-200 Peanut Shelling Machine

This small groundnut shelling machine mainly contains 3 parts, the destoner for peanuts, conveyer and the groundnut sheller. It features compact structure, stable operation and less noise. One of the advantages of the groundnut shelling machine is that the conveyor part is effective and economical. The groundnuts can be conveyed by the machine-made wind directly. We have different model according to customer's requirements of capacity. It has reliable quality, excellent performance, and low rate of processing of peanut crushing.

Peanut groundnut machine mainly advantage:

1. Low price

2. High efficiency, low breakage

3. Simple structure, easy operation

4. Small weight and move easily

5. Durable and long working life

Technical data of groundnut shelling machine:

Capacity: 200KG/H

Powder:2.2KW

Voltage:220V or 380V

Packing:630*600*930mm

Weight: abt.40kg

What should be noticed when using peanut sheller for shelling?

During the shelling process, there are a lot to be noticed when using the peanut shelling machine, the following are the main points:

1. Close the telescopic hopper before feeding. After the hopper is full of peanut fruits, open the gate slowly and close the outlet gate at the same time. When the peanut kernels and fruitlet are gathering in gravity separation sieve for about 20 to 30mm, then open the gate slowly so that peanut kernels can flow out smoothly and fruitlet would be left. In the production process, the kernel gate should be adjusted to the appropriate place, otherwise it will increase the breakage rate and reduce the cleaning degree.

2. When in the use of the peanut sheller, if the discharging gate of the kernel is open, but the peanuts can not be discharged, you can adjust the connecting rod screw to the long direction, then the peanuts can be smoothly discharged.

3. When in the use of the peanut sheller, if too many peanut kernels are found in the shells, you should reduce the air inlet of the fan. If there are too much shells in the feed inlet, you need to increase the air inlet of the fan appropriately.

4. When the peanut sheller works, the gravity sieve should be placed horizontally to make the impurity rate of peanuts from the outlet meet the requirement.

5. If the productivity of the peanut sheller is reduced in the process of using, you should adjust the belt tension of the fan to improve the productivity.

The peanut shelling machine produced by our company has the advantages of stable and reliable performance, good shelling effect and high productivity for processing various peanuts. Welcome to select and purchase.